FROM INNOVATION TO ENERGY EFFICIENCY

Our innovations in wafer production have a strong impact on increasing the energy efficiency of chips. This has a particular impact on smartphones, computers including servers, household appliances and electric vehicles.

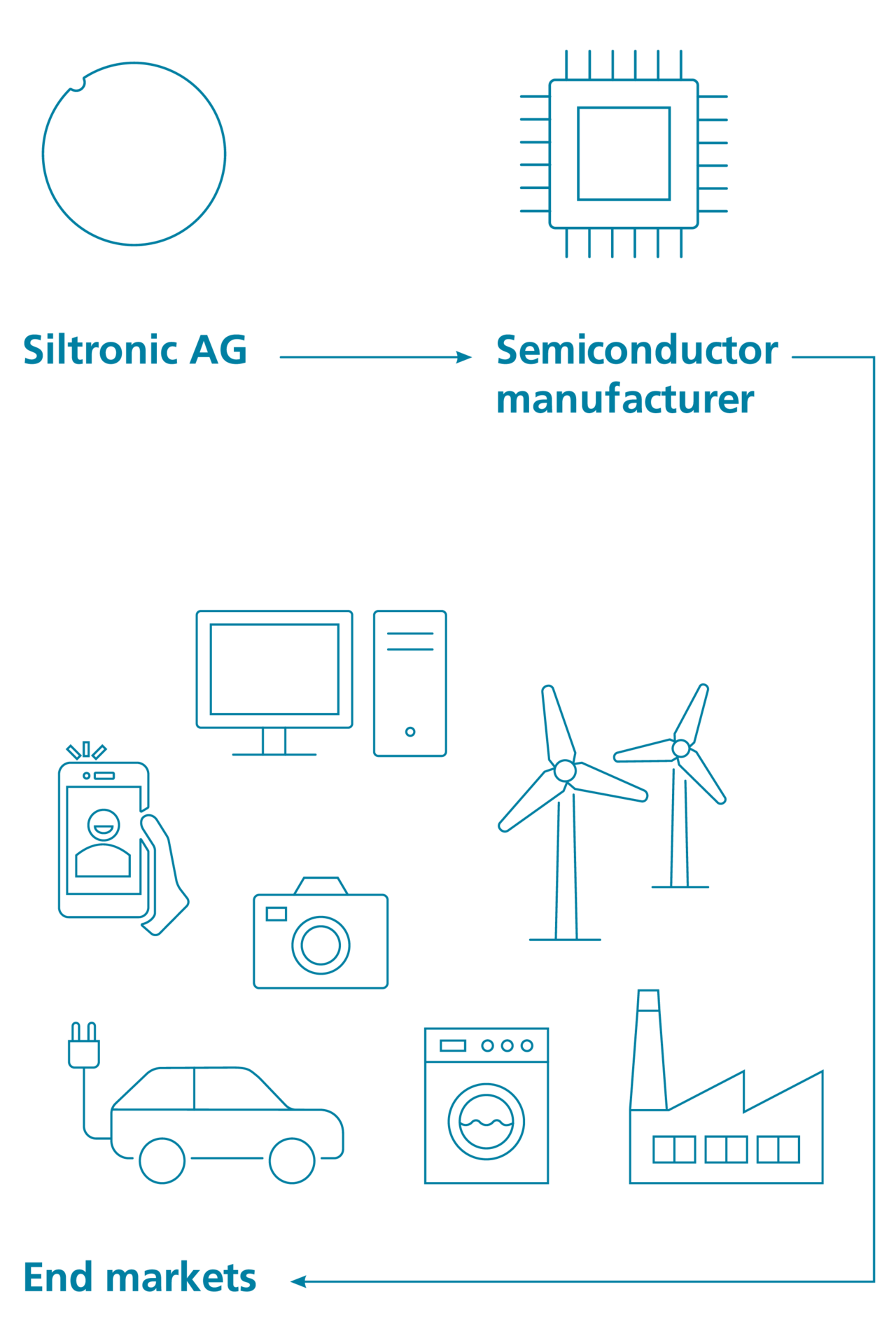

Siltronic AG

Hyperpure silicon wafers are the basis for almost all semiconductor devices and consequently represent an essential basis for the world’s electronics industry.

Manufacturers of semiconductors

Our wafers are very closely linked to computer chips because our customers – the manufacturers of semiconductors – transform wafers into chips through physical and chemical processes.

End markets

The most important end markets for demand for our wafers are smartphones, computers, servers, consumer electronics including household appliances, industry and automobiles. Almost all of our wafers go to these six end markets.

Annual report

Audited information and key figures on sustainability at Siltronic can be found in our current annual report.

Related information

Research and development for environmental innovations

Our research and development is aimed in the following directions in order to contribute to environmental and climate protection with our products:

Cooperation with customers as the key to success

Many of our projects require close and continuous cooperation with our customers. To this end, we work on projects with our technologically leading customers as part of joint development programs, taking care to cover a broad spectrum of semiconductor end applications. We also work together with research and academic institutions.