Many electronic devices would be inconceivable without the shiny gray-black metalloid silicon, which is the second most commonly occurring element after oxygen. Whether for smartphones, televisions, or cars: silicon plays a key role today wherever semiconductor technology is used. In the form of hyperpure silicon wafers made from silicon crystals in a complex process, silicon is the foundation of the electronics industry around the world. Siltronic, developer of the first silicon wafer in 1962 and today one of the global leaders in the wafer industry, offers the highest quality, innovative silicon wafers, positioning the company as an important partner to the quality-oriented semiconductor industry around the world.

Siltronic’s product portfolio is extensive and ranges from non-polished wafers to epitaxial wafers with diameters up to 300mm. The wafers are manufactured from monocrystalline silicon ingots that have been made using either the Czochralski process (CZ) or the float zone method (FZ). Because the crystal properties are critical for the semiconductor component’s function, a number of different processes are available to ensure the optimal material properties for each customer application. Particularly critical is the specific application of doping substances and the crystals’ cooling profile. The wafer’s surface condition is also tailored to the specific use. It ranges from simply sliced to polished on both sides and epitaxial surfaces.

Safety data sheets

How to make a silicon wafer

A wafer is a slice of silicon roughly 1 millimeter thick that has an extremely flat surface thanks to procedures that are technically very demanding. The subsequent use determines which crystal growing procedure should be employed. In the Czochralski process, for example, the polycrystalline silicon is melted and a pencil-thin seed crystal is dipped into the molten silicon. The seed crystal is then rotated and slowly pulled upwards. A very heavy colossus, a monocrystal, results. It is possible to select the monocrystal’s electrical characteristics by adding small units of high-purity dopants. The crystals are doped in accordance with the customer specifications and then polished and cut into slices. After various additional production steps, the customer receives its specified wafers in special packaging, which allows the customer to use the wafer immediately in its production line.

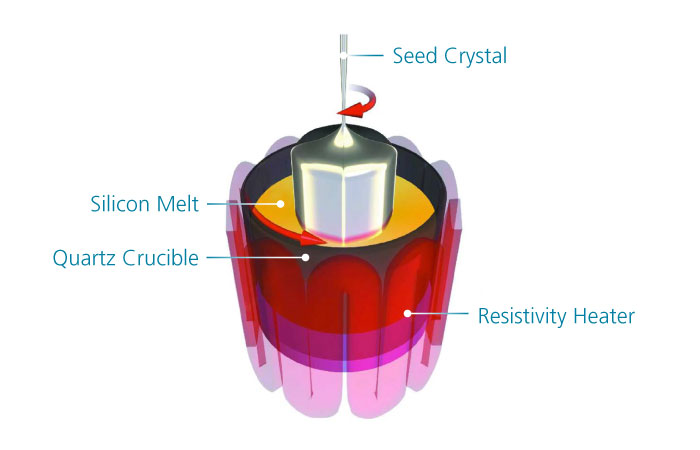

Czochralski process

Czochralski process

Today, a large portion of the silicon monocrystals are grown according to the Czochralski process, which involves melting polycrystalline high-purity silicon in a hyperpure quartz crucible and adding the dopant (usually B, P, As, Sb). A thin, monocrystalline seed crystal is dipped into the molten silicon. A large CZ crystal then develops from this thin crystal. Precise regulation of the molten silicon temperature and flow, the crystal and crucible rotation, as well as the crystal pulling speed results in an extremely high quality monocrystalline silicon ingot.

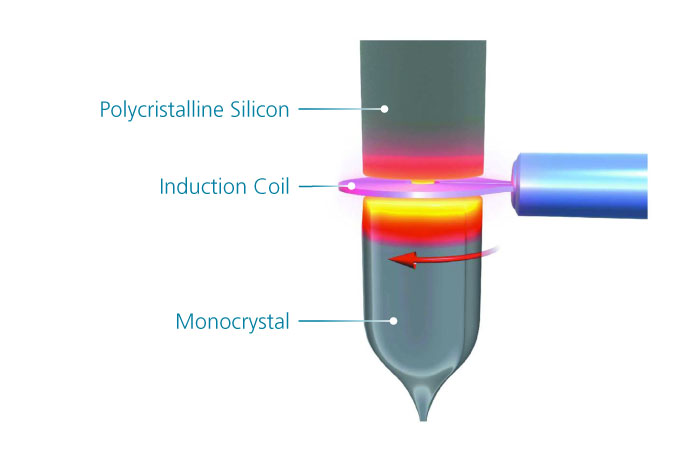

Float zone method

Float zone method

Monocrystals manufactured according to the float zone method are ideal for use in power semiconductor components, such as IGBTs. A cylindrical polycrystalline silicon ingot is mounted over an induction coil. A radio frequency electromagnetic field helps melt the silicon from the lower part of the rod. The electromagnetic field regulates the silicon flow through a small hole in the induction coil and onto the monocrystal that lies below (float zone method). The doping, usually with B or P, is achieved by adding gaseous substances.

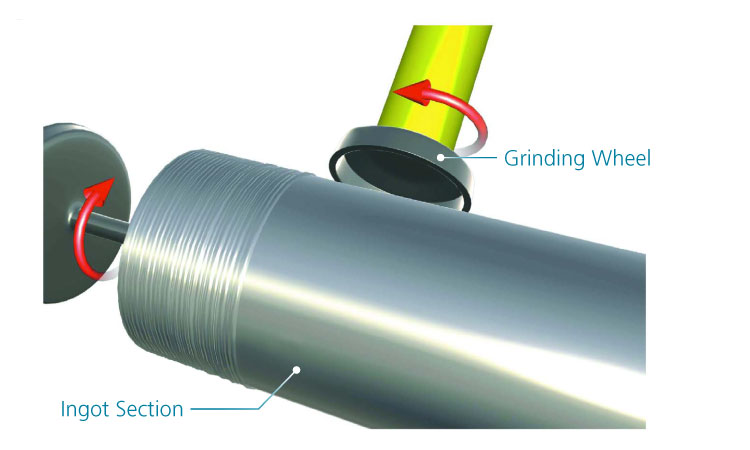

Cylindrical grinding

Cylindrical grinding

After segmenting and comprehensive quality control, the monocrystalline CZ or FZ silicon pieces are prepared for the wafering process. This means first precisely aligning the crystals, then cylindrical grinding of the ingot pieces to the required diameter. The final step is grinding orientation markings, such as notches for large-diameter wafers or straight edges (flats) on the side of small wafers.

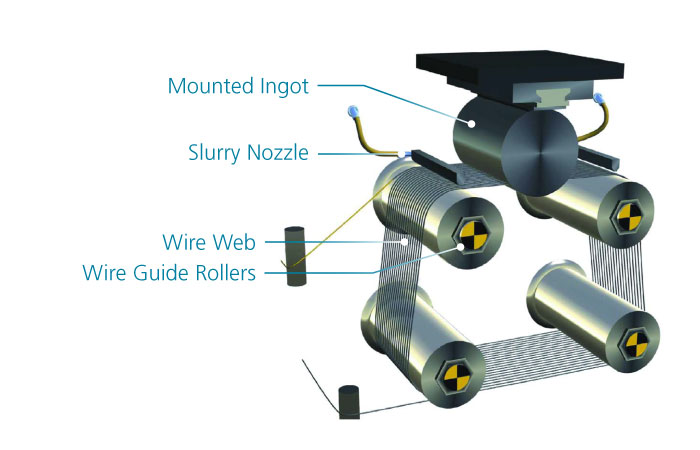

Wire slicing

Wire slicing

The first step when wafering the silicon ingots is multi-wire slicing, which is the slicing method commonly employed today. A very thin metal wire, which can be many miles long, is pulled over the wire guide rollers in such a way that a wire web with very precise spacing is spanned. Nozzles apply the slurry to the web while the silicon ingot is slowly pushed through the web. This technology makes it possible to slice complete silicon ingots into hundreds of silicon wafers in just one step. The individual process parameters must be carefully monitored in order to guarantee that the wafers are uniformly thick and that the two faces of each wafer are parallel to each another.

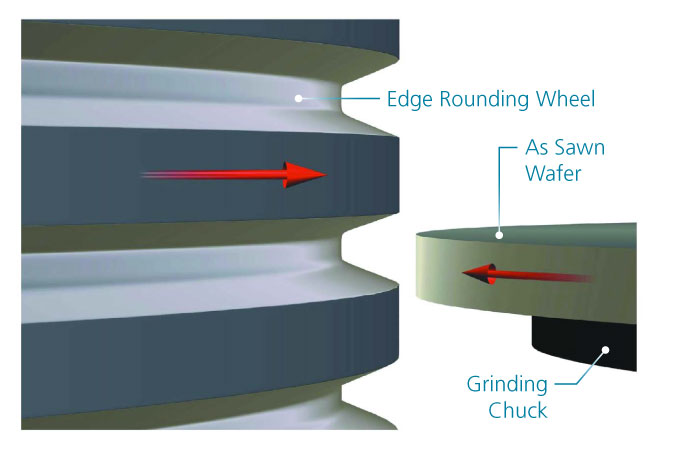

Edge rounding

Edge rounding

Monocrystalline silicon is a very brittle material with a high risk of breaking. Special care is consequently needed in order to avoid mechanical damages on the edge of the wafer.

The unrounded silicon wafer is mounted onto a grinding chuck and a profile rounding wheel rounds the edge of the wafer. The edge profile is rounded to match the customer specifications. Each wafer is optimized in order to avoid processing damages and maximize the yields in the component processes, such as CMP and lithography.

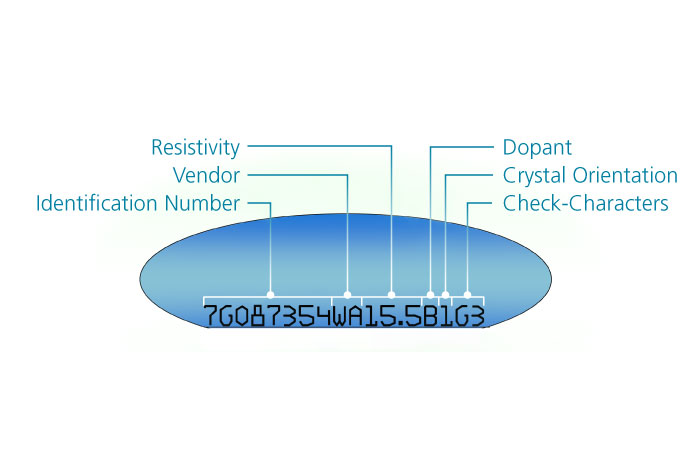

Laser marking

Laser marking

Laser marking is used to identify individual wafers or wafer batches in order to allow manufacturing traceability. Laser marking can take place in accordance with either industry standard or customer specifications. As a rule, the markings contain information on the wafer supplier, some technical information, and an individual wafer number.

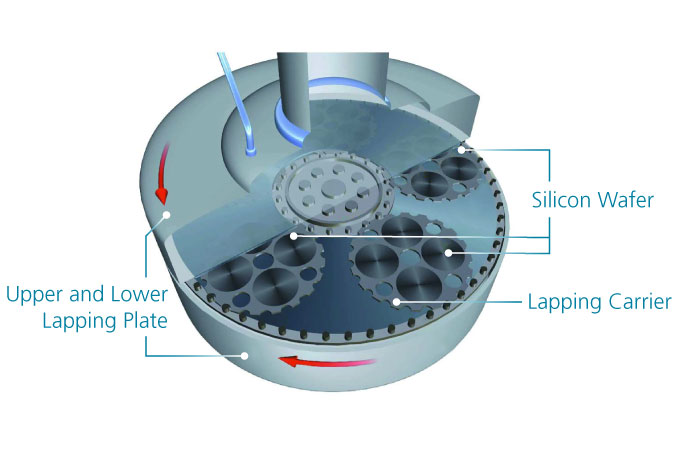

Lapping

Lapping

After the wafers have been sliced and the edges have been rounded, the wafers are lapped (or alternatively ground) in order to increase the parallelism of the silicon wafer surfaces and to remove any damage below the surface caused by the slicing process. For lapping, the silicon wafers are held in carrier wheels (lapping carriers) between the upper and lower lapping plates, which rotate in opposite directions. The addition of an abrasive (lapping slurry) helps remove roughly ten micrometers of silicon from each wafer surface.

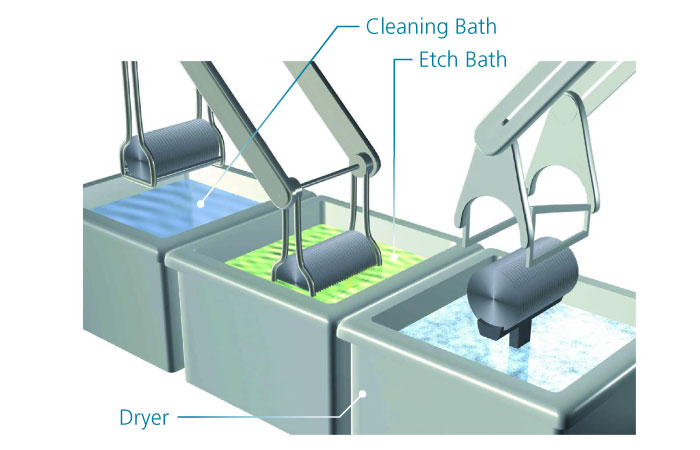

Cleaning and etching

Polishing

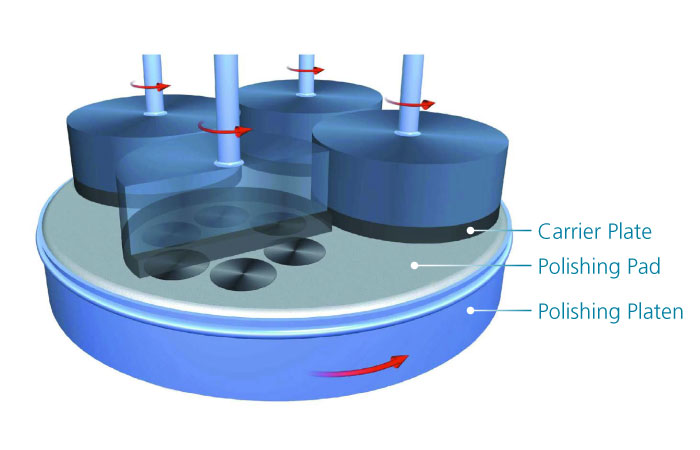

Polishing

Polishing makes the silicon wafer surface smooth as glass and further improves the flatness. Wafers with a diameter of 200mm or less are usually polished on one side. The wafers are mounted on support plates and pressed against a polishing cloth that lies on a polishing plate. Wafers with a diameter of 300mm are polished on both sides. Like in the lapping process, the wafers are held by plates and simultaneously polished on the front and back by upper and lower polishing plates. The polishing agent (polishing slurry) and the pressure scheme determine the finished wafer’s surface quality and flatness.

Epitaxy

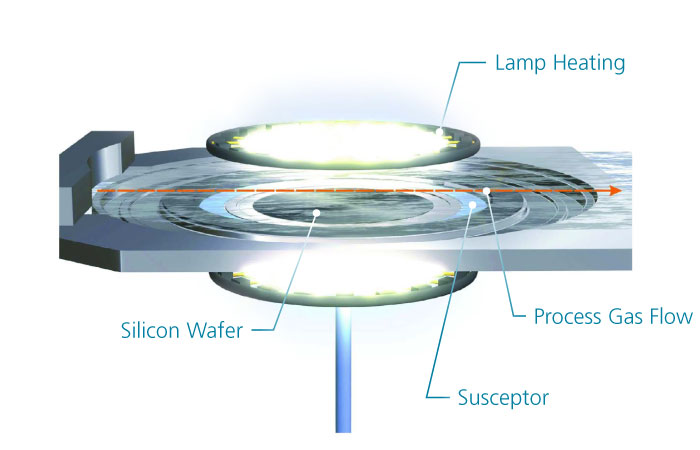

Epitaxy

Applications with the toughest requirements call for silicon wafers with an especially high surface quality. In these cases, a thin, defect-free crystal layer is additionally deposited onto the polished surface from the gas phase. To apply the epitaxial layer, the silicon wafer is fastened to a susceptor and heated to a high temperature with the help of infrared lamps. The process gas flow and temperature are carefully controlled in order to create an epitaxial layer with a very homogeneous resistance and thickness profile.